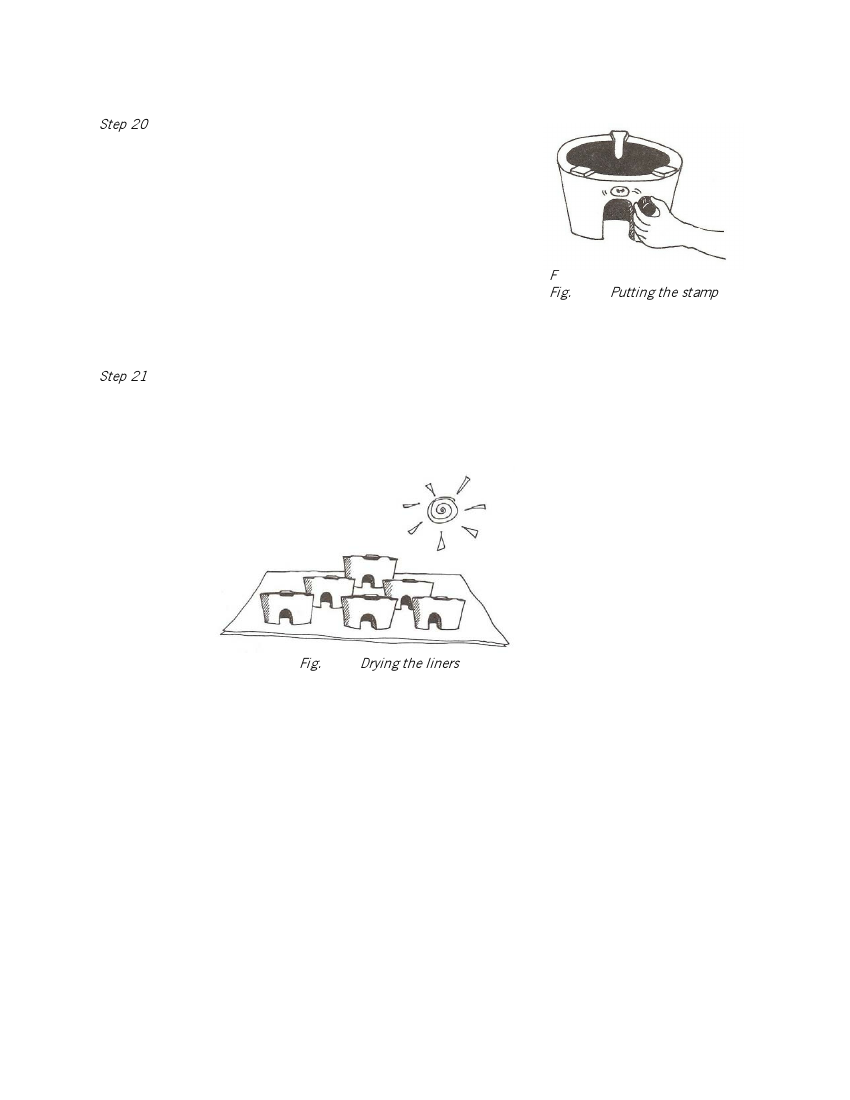

Step 20

Smooth the stove, using a little water and a plastic spatula. Complete

the stove by decorating or putting an identifying stamp on it. This

stamp should identify where the liner was made. It can be carved in

wood or rubber like an office stamp.

F

Fig. 4.25 Putting the stamp

The stove has to be attractive and functional. If you want to sell it, someone ~ has to like its appearance to

want to buy it.

Step 21

Dry the stove liners for two to three weeks. If the climate is hot and dry, cover the liners in polythene or

sacking for the first week to prevent them from drying too fast and cracking. If the climate is damp, the

liners can be left to dry without being covered. When the liners look and feel completely dry, they should be

put in the sun on a dry surface, for two to three days.

Fig. 4.26 Drying the liners

Notes on drying stove liners

Stove liners have much thicker walls than most traditional pots. This means that they will take longer to

dry. It is important to dry the liners as slowly and evenly as possible.

DO NOT

DO

put wet liners in direct sunlight to dry

put wet liners in a draughty or windy place to dry

put wet liners directly on a cement floor

put wet liners in a hot tin-roofed shed without covering them.

put wet liners in a cool humid place for the first few days of drying

put cardboard, sacking, cloth, dried grass or leaves under the liners, especially if they are

to stand on a cement floor

cover wet liners for the first few days of drying with sacking, cloth, cardboard or even

banana leaves. If you use polythene, make small holes in it to allow some moisture to

escape.